Yokogawa YTA610 Temperature Transmitter

Dual-compartment housing realizes high resistance

capability to harsh environments

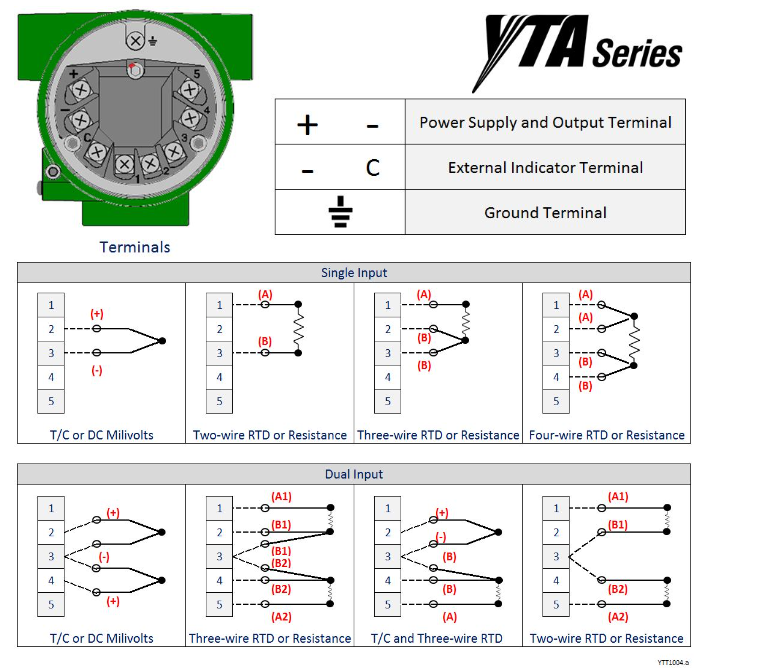

The type of sensor input is user-selectable from

thermocouples (T/C), RTDs, ohms, or DC millivolts

Parameter configuration by the push button offers

easy and quick setup for parameters

Yokogawa temperature transmitter yta610 temperature transmitter

YTA610 has high precision, high stability and reliability. The shell structure adopts a reliable dual -chamber structure. Sensor input can select single input or dual input. Can enter RTD, thermocouple, resistance or DC voltage signal. It converts the sensor input into a 4-20mA DC analog signal or a live bus digital signal. Provide Hart 7 protocol or Foundation ™ Fieldbus ITK 6 version. Dual input can accept the temperature difference or average calculation of the two sensors and the implementation of the sensor backup function. The sensor backup function can be automatically switched from the main device to the backup equipment when the sensor fails. Using the local parameter switch on the indicator, you can easily set up on -site work.

Double sensor input

YTA610 can be input in dual transmission. With the processing capacity of the transmitter, the dual input can be used to provide fault sensor backup, average temperature or temperature difference measurement.

Sensor matching

Henghe YTA610 uses the IEC60751 standard to define the relationship between the resistance and temperature of the RTD sensor. This relationship is called a standard curve. Sensor manufacturers use the same standards, but due to the construction process, each sensor has a temperature/resistance relationship. This is called the real RTD curve. (The real RTD curve belongs to the 60751 standard tolerance zone of the Electricity Committee) In the 1920s, Hugh Langbur Karda and Fan Dussen developed a set of coefficient standard curves to match the real RTD curve; therefore, it eliminated it. Error caused by the difference between the two curves. Henghe YTA610 has the CM1 option, which can accept these coefficients to adjust the standard curve matching the real RTD curve sensor; eliminating this error improves the accuracy of the YTA610 /sensor system.

YTA Daedal insight provides valuable information during the entire life cycle of the device.

Sensor selection: -Engineering and purchasing-

Simple product lineups and extensive recognition help customers choose the correct product.

Easy to install: -The configuration and debug-

Various methods of configuration equipment help reduce installation and configuration time.

Rich information: -The operation and observation-

Valuable diagnostic information can improve process efficiency.

Expert solution: -Dao Maintenance and Service-

Providing timely maintenance information helps reduce maintenance costs.